All Boschert punching and bending machines can be programmed using our Cad/Cam Software in your construction office.

BG Cut

BG Cut |

||

|

Boschert offers a full range of CAD/CAM capabilities for CNC Punch, Laser and Plasma machines, including support for sorting and stacking devices attached to your machine. Advanced technology combines Design, Automatic and Manual Processing, Automatic Nesting, efficient NC Generation, Graphic and Simulation. BG Cut is the only system which has integrated CAD/CAM capabilities in the same module: Geometry, Dimensions and Technology (Punching/Cutting) are completely associative – when the Geometry is modified, Dimensions and Technology are automatically updated! BG Cut supports a wide range of machines and has a powerful solution for porting parts from one technology or machine type to another, such as from Punch to Laser. BG Cut is affordable, user-friendly and comes complete with comprehensive documentation and support, from installation to production. |

||

Autonest

Autonest |

||

|

Fully automated nesting for quick, easy and efficient solutions • Hole Filling – interior holes in parts are identified and filled with compatible parts • True Shape or Rectangular Nesting – select the best strategy for faster solutions • Multiple Material Nests – parts from different materials are sorted automatically and nested on appropriate sheets • Multiple Sheet Solutions – nesting solutions can be generated on different sheet sizes, selected automatically for efficiency and the minimal number of sub-nests |

BG Bend

BG Bend |

||

|

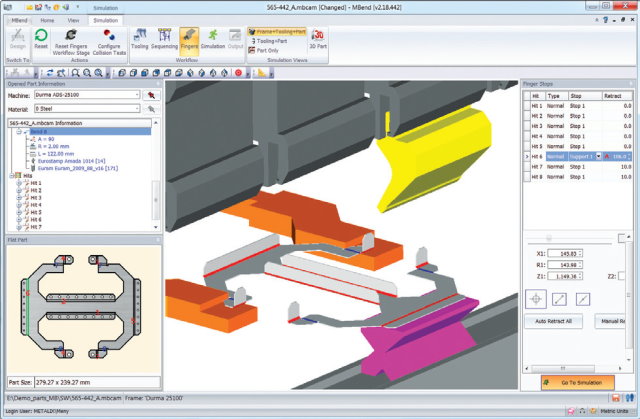

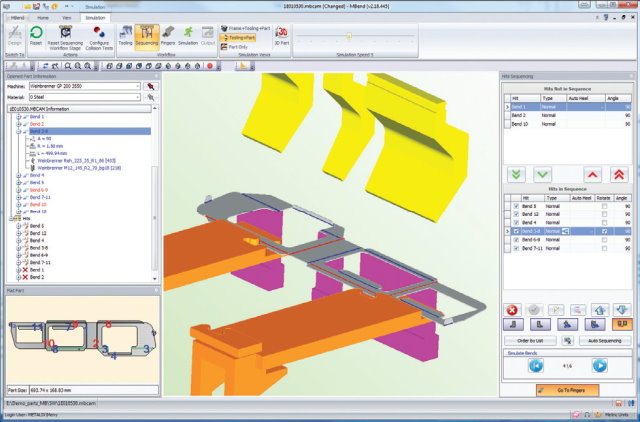

BG Bend is an application for programming and simulating CNC Press Brakes, used to maximize production resources. It loads an existing drawing, calculates bending sequence, suggests the tools and backstops to be used, and produces the NC program. Benefits: • Faster design-to-production times with automated features • Offline programming translates to minimal machine down-time • Collision-less bend sequences mean reduced stock wastage • Production-ready bend sequences with fewer experts on-hand • Easy switch between machine configurations for shop-floor production optimisation • Improved fabrication quality thanks to better production planning ◦ Increased production avoiding costly errors, with Collision Detection ◦ Integration with other Metalix products such as cncKad and MetalixUnfolder ◦ User friendly • Better use of your resources with: ◦ Enhanced Productivity ◦ Intuitive workflow for ease of use ◦ Accessible Tool Library for quick tool additions ◦ User-independent machine configuration What does it do? • Directly transfers parts from SolidWorks®, Solid Edge®, and AutoNest® Invertor®, as a 3D model or as a 2D DXF file • Imports and unfolds IGES and STEP 3D parts • Allows Bend Sequence Selection with Collision Detection • Enables Automatic and Manual Tool Selection based on material, machine and tool properties • Allows Automatic Fingerstop Positioning with graphic controll of all axes • Runs 3D Bending Simulation with Collision Detection • Generates NC programs directly to the machine control, in native controller format (Delem, Cybelec, Amada, etc.) • Creates detailed Manufacturing Reports |

Copper

Downloads